Drying Screed - A Quick Guide

Types of Screed Used in the UK by Underfloor Heating Companies

What Types of Equipment Can Be Used To Speed Up The Process Of Drying Screed?

Drying screed is a critical stage in the installation process of a screed flooring system. The process of drying screed can affect the final result of the flooring and its durability. In this article, we will explore different types of screed flooring, screed setting and drying times, debunk myths about drying screed, discuss the variables that affect drying time, and explore the different types of screed used in the UK by underfloor heating companies.

Types of Screed Flooring

There are three types of screed flooring: traditional screed, flowing screed, and fast-drying screed. Traditional screed is a mixture of cement, sand, and water that is laid on a concrete subfloor. It is commonly used in residential and commercial construction projects. Flowing screed is a self-leveling screed that is poured onto the subfloor and provides a smooth finish. Fast-drying screed is a type of screed that dries more quickly than traditional screed.

Screed Setting and Drying Times

Screed setting time refers to the time it takes for the screed to harden enough to walk on without damaging the surface. This usually takes between 24 and 48 hours. Screed drying time, on the other hand, refers to the time it takes for the screed to fully dry and be ready for the installation of the final floor covering. This can take anywhere from a few days to several weeks, depending on the type of screed used, environmental conditions, and other variables.

Myths About Drying Screed

There are many myths surrounding the drying of screed that are not true. One common myth is that screed dries faster in warmer weather. While it is true that warmer temperatures can speed up the drying process, extremely hot temperatures can actually cause the screed to dry too quickly, leading to cracking and other issues. Another myth is that leaving the windows open will help the screed dry faster. In reality, this can cause fluctuations in temperature and humidity, which can slow down the drying process.

Variables That Affect Drying Time

Several variables can affect the drying time of screed. These include the type of screed used, the thickness of the screed, the ambient temperature and humidity, and the presence of underfloor heating. Other factors that can affect drying time include ventilation and the use of dehumidifiers or fans.

Types of Screed Used in the UK by Underfloor Heating Companies

Underfloor heating is becoming increasingly popular in the UK, and many companies use different types of screed in their installations. Some of the most commonly used types of screed include liquid screed, which is a self-leveling screed that provides an even finish, and sand and cement screed, which is a traditional screed that is laid on a concrete subfloor. Other types of screed used by underfloor heating companies in the UK include fast-drying screed, flowing screed, and fiber-reinforced screed. For more information, read our detailed article on the different types of screed here.

How Long Does It Take to Fully Dry Screed?

The length of time it takes for screed to fully dry can vary depending on a number of factors. In general, it can take anywhere from a few days to several weeks for screed to dry completely. Fast-drying screed can dry in as little as 24 hours, while traditional screed can take up to 28 days to dry completely. The thickness of the screed, the ambient temperature and humidity, and the presence of underfloor heating can all affect drying time.

What Types of Equipment Can Be Used To Speed Up The Process Of Drying Screed?

Once poured, screed needs to be left to dry and cure before it can be walked on or have flooring installed on top of it. However, the drying process can take several weeks, which can be a significant inconvenience for construction projects where time is of the essence. Fortunately, there are several pieces of equipment that can be used to speed up the drying process of screed.

Dehumidifiers

Dehumidifiers are machines that remove moisture from the air. They are commonly used in construction to dry out damp areas and speed up the drying process of materials such as screed. By lowering the humidity in the air around the screed, dehumidifiers can help to draw out moisture from the screed and promote faster drying.

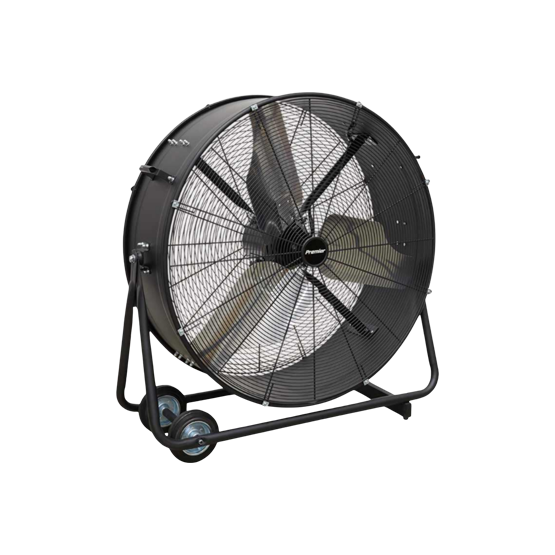

Air Movers / Fans

Air Mover Fans (also referred to as Industrial fans) are another useful tool for drying out screed. By circulating the air around the screed, they can help to evaporate moisture from the surface of the screed and promote faster drying. This can be particularly effective when used in conjunction with dehumidifiers, as the combination of low humidity and increased air circulation can help to speed up the drying process even further.

Mobile Electric Boilers

Underfloor heating systems can also be used to speed up the drying process of screed. By heating the surface of the screed, underfloor heating systems can help to promote evaporation and speed up the drying process. This is particularly effective when used in conjunction with dehumidifiers and fans, as the combination of low humidity, increased air circulation, and heat can help to dry out the screed much faster.

As well as the equipment listed above, Rapid drying screed can also be used. Rapid drying screed is a type of screed that has been specifically designed to dry out much faster than traditional screed. This type of screed is typically made using a different mix of materials, which allows it to dry out much faster than traditional screed. Rapid drying screed can be particularly useful in construction projects where time is of the essence, as it can significantly reduce the time required for the screed to dry. You can learn more about the different types of screed from this article.

In conclusion, there are several pieces of equipment that can be used to speed up the drying process of screed. Dehumidifiers, fans, underfloor heating systems, and rapid drying screed can all be used to help promote faster drying and reduce the time required for screed to dry out. By using these tools in combination, construction professionals can significantly reduce the time required for screed to dry, allowing them to complete projects more quickly and efficiently.